In the 1990s, the American supercapacitor manufacturer EEStor spent several years to invest a lot of financial and material resources in how to make progress in order to change the status quo of supercapacitor stores Farad capacitor In the research and development of energy density, it is expected that the super capacitor will rise to a new level in production and application through its own skills. At that time, EEStor won a huge amount of research and development funds, and also reached strategic cooperation with ZENN, the electric vehicle motor supplier. However, many scientists who participated in this research have come to a regrettable conclusion: we would like to break the market deadlock of supercapacitors, but the existing skills cannot complete this policy.

Although supercapacitors have been developed for many years, the number of actual manufacturers is very small. Some manufacturers, faced with the status quo of incomplete development of Farad capacitor skills, dare not invest and take a wait-and-see strategy, waiting for the market to present an example of entering this field and achieving success. Others are convinced that as long as Super capacitor manufacturer Its production cost has been greatly reduced, and its rapid popularization can be achieved only by its fast charging and discharging characteristics. EEStor, an American supercapacitor manufacturer, belongs to the latter. In 2015, the global super capacitor market reached 17.346 billion US dollars, and in 2015, China Super capacitor module The market scale is close to 3.5-4 billion yuan. According to industry research, the global super capacitor market is expected to have a compound annual growth rate of more than 20% in the next five years.

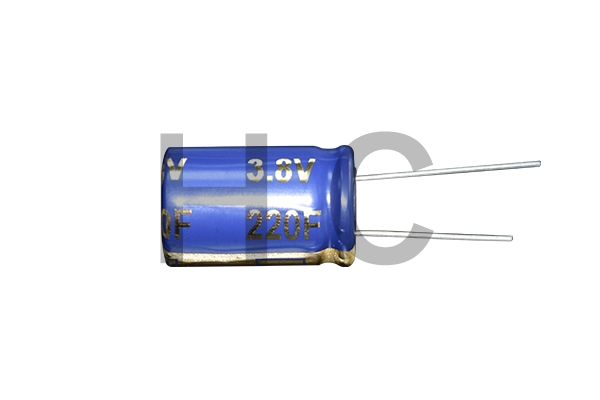

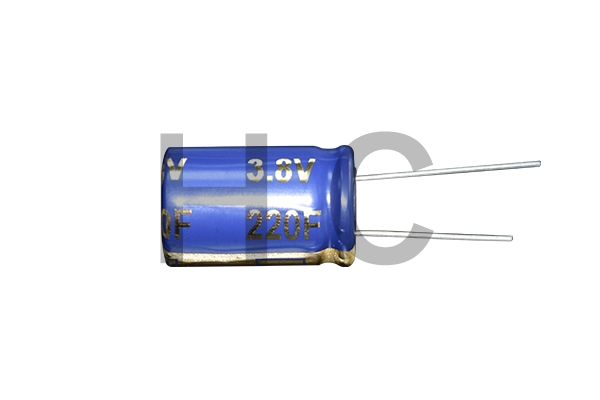

Some sophisticated battery skills, such as lithium-ion batteries, nickel hydrogen batteries and lead-acid batteries, have been practiced, because their charging and discharging process will occur chemical reactions, which restricts their development. Therefore, the improvement of battery function mainly depends on the improvement of packaging skills and the strengthening of preparation process. Supercapacitor technology is still in its infancy and has high development potential. Compared with chemical batteries constrained by the fixed structure of batteries, supercapacitors mainly rely on the physical function of materials for energy storage. At the same time, compared with other mainstream batteries, supercapacitors still do not make full use of the potential of surface energy storage, and there is no disjointed "workshop" type production form and lack of raw material supply. Avoid overheating the capacitor during welding. If the capacitor is overheated during welding, the service life of the capacitor will be reduced. For example, if the printed circuit board with a thickness of 1.6mm is used, the welding process should be 260 ℃, and the time should not exceed 5s.